3D Printing can be Frustrating

I figured out how to use Minimum Layer Time and Lift Head in Cura. So now my pieces with small tops don’t melt. For example, my tiny 20mm tall Koala gets to keep his ears!

I made a spray can holder for Abigail so she could spray paint stuff more easily with her kid hands. Unfortunately, it broke on a layer line almost instantly :-( I can’t think of a good fix. I printed on an angle so the collar would have more strength in the vertical direction. But now it snaps like this. I need strength in more dimensions! I tried printing this with Gradual Infill Steps so I’d get 50% infill at the business end and 50/3 = 16.6% infill at the handle end. But that apparently wasn’t enough. :-(

I’m just going to buy it on amazon for $6!

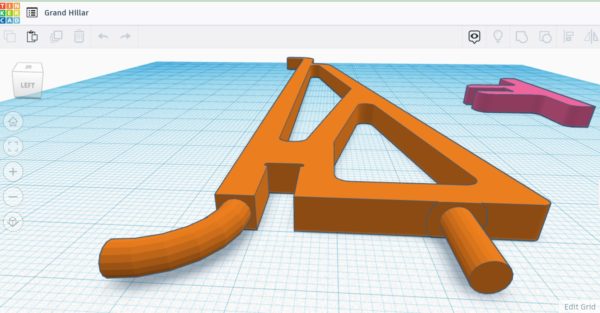

I tried making pegboard pegs but it’s not going great. Actually, I’m proud for this being the first piece that I downloaded and modified in Tinkercad! I borrowed the design from Thingiverse. I replaced the original pegs with a 3.6mm cylinder peg on the bottom and a 3.6mm truncated torrus on the top. I was thinking that 3.7mm might fit a tiny bit better But it broke as I was mounting it. PLA is a frustratingly weak material!

I’ve printed a few fun things though! Abigail and I made a sign with her name and her camp name, Kids for the Bay. And I made her an Odd Squad badge, with a custom number on it, and painted it gold (it looks pretty good!) And I printed a few fun turtles.

There are a few pi pencil cups on the internets. Printing it so that it looks great is proving difficult! I see one on Shapeways for $50, printed all nice-like! I think I might get it.

Wouldn’t this be nice to have?

But the toothbrush holder has made it all worthwhile! Sublime in design, Useful in usefulness!