.

.

Here's several Zagi making hints I've found online. Most of them came from ClubZagi.com and YourZagi.com. The best reference is the Zagi Manual pdf from Mike's Hobby Shop. Cliff at Atlanta Hobby has been my pleasant & responsive pushe... Zagi dealer. Those sites have a lot more tips than I list here. Check 'em out. I've rewritten these hints with my own comments.

Zagi Manual (9meg zip) - good

Use Shoe Goo or other silicon based adhesive to attach the motor to the plastic pod this keeps it from coming out on hard impacts with the ground.

Use the old 3M 77 spray adhesive. It was discontinued in 2002 or so. But don't use the new stuff in the purple and black can!! They changed the formulation to be better for the environment but the new acetone formulation eats the foam. I don't know what you should use instead, sorry!

. .

|

Add a strip of plastic to your batteries so they will be easier to find when

they eject from the plane on impact. My strip is only about 4" (a lot

shorter than the photo)... that's easier to tuck in for flying.

|

| When the speed control is put in the plane, loop the wires around itself and put a zip tie on them so that when the battery is pulled out of the plane in the event of a crash the strain is on the motor not the speed control. |

|

| Cut the nose back a little from the leading edge of the plane. This will let the foam absorb some of the impact not the plastic. This ultimately didn't save my tip from cracking, but what are ya gonna do? |

|

|

Use the extra foam that is in the kit to make a landing and launching skid

on the bottom of the plane. I haven't done this yet. I used the extra foam

for other little things. Oop!

|

| The props have to be turned around were the lettering is toward the back of the airplane as shown in the picture. |

|

|

We found that the lexan tips that it comes with cause the plane to wonder

find some coraplast sign material and cut your own wing tips this will help

stability in flight. Use 2 mm coroplast... most roadsigns are 4 mm.

|

|

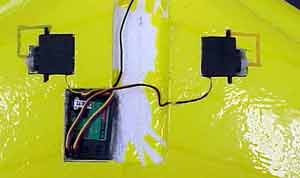

When installing the receiver in the Zagi 400 X the instruction call for it

to be placed in the nose of the airplane. Don't put it there! Mount it in

the wing on either side of the electronics pod this will protect the

receiver in a crash. Also note the servos are laying down in the wing not

standing upright.

|

|

|

Note receiver is half way under tray with xtal on the outside for easy

changing if necessary. The receiver will be covered by the colored tape when

the tray is taped on. (Zagi 400X)

|

-------------------------------------------------------------------

When

you examine the wing core, you might notice strands or "hairs" of glue

and hard plastic. Gently remove these with your fingertips or gently pry up the

tip of one strand with a knife to get it started. If your kit included a small

block of EPP foam, this can be used for gently rubbing off all of the excess

foam "hairs".

When

you examine the wing core, you might notice strands or "hairs" of glue

and hard plastic. Gently remove these with your fingertips or gently pry up the

tip of one strand with a knife to get it started. If your kit included a small

block of EPP foam, this can be used for gently rubbing off all of the excess

foam "hairs".

You might find some fairly thick pieces that wander across the wing. This is a

normal side effect of the hot wire used to cut your core. Gently pry them up.

The truly large ones might leave a small indentation in the foam after you

remove them. The foam will slowly expand out again over a few hours so try not

to worry about them. This is normal.

-------------------------------------------------------------------

Use a coat hanger to hang it on the wall.

-------------------------------------------------------------------

put strapping tape on the inside of the battery tray, top and bottom. To keep the tray in one piece.

-------------------------------------------------------------------

When you get your first roll of Monocote, know that before you try to stick it to your plane, you should peel off the very thin, transparent protective coating. My first time, I didn't catch this important point and just cranked up the iron... it stuck, but crappily.

-------------------------------------------------------------------

If your elevon comes off during flight, exciting things are bound to happen. The Mylar hinge tape provided with the kit is fine, but there is a better solution which can be applied to all of your aircraft. Winter flying plays havoc with the stock hinge tape as too many fliers have discovered 300 feet AGL (above ground level). Strapping tape does not seem to be as susceptible to thermal weakness as the Mylar hinge tape is. If you originally used the hinge tape, check it during the winter if you fly during cold weather, and certainly before the first flight after winter. At some point, replace it with strapping tape.

Before applying your hinge tape, make sure you mask off the elevon and lightly spray some Super 77 on it. Let it dry before applying the tape. Although S77 is not required when applying strapping tape, it should be done regardless to ensure that your hinges will not come off until after the aircraft is destroyed.

The best example of this has been done by Andy Willetts and is show here.

Some have used the over-under hinge, then extended their Ultracote or a film covering over and around the elevon for additional strength and clean looks. If you do this, make sure that you have not added a tremendous amount of resistance that your servo now has to overcome.

Buzzman has a great picture that shows an alternative method for hinges that you can view here.

------------------------------------------------------------------

http://www.yourzagi.com/covering.htm